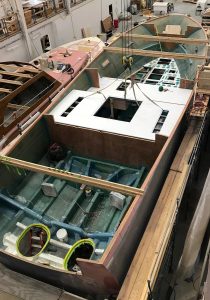

Two interesting new techniques are being utilized in the construction of this 57’ high-performance cruiser. First, to achieve the expected 39 knots from the Volvo Penta’s IPS 1350 integrated propulsion system, the yacht is engineered with weight-control and strength as a priority.

Stephens Waring Yacht Design provided innovative composite construction details that hybridize wood and fiberglass into a contemporary build method.

Improving Ergonomics in Boat Building

Second, for this new project, Lyman-Morse is employing a new overhead crane system to facilitate an ergonomically efficient building environment for the boat building crew. Taking the module-building practice employed on Anna to the next level, they will build the hull in four separate parts:

- The bottom module, which is about 50’ in length by 15’ in width that includes the stem of the boat

- Both topsides sections, port and starboard, that run from the stem aft to the transom

- The curved transom section

Modular Wood-Composite Boat Building

The process starts with the jig that was precisely cut by Lyman-Morse’s Haas GR-712 CNC machine from direct digital inputs. Once assembled, the jig yields such a perfect form that the wooden sheathing for the bottom along with the pre-made curved transom can be installed.

Meanwhile, the tricky internal longitudinal structural stringers, using CNC machined foam formers that have their structural epoxy laminate completed, are constructed simultaneously with the bottom sheathing. To eliminate the ergonomically difficult work of working on an upside-down part, the bottom is lifted off the jig using the overhead crane, rotated to the upright orientation and placed in a cradle which then allows the inner structural laminate to be installed and epoxy-infused.

Next the pre-made internal longitudinal stringers are lifted and placed in reliefs that have been machined into the jig to perfectly locate them in the hull. Then the bottom, with its inner skin installed, is lifted, rotated back to the inverted orientation, and put back on the jig. An epoxy adhesive is used to bond the longitudinals to the hull bottom.

The topside planking follows, finishing up with a structural epoxy-impregnated laminate as the outer skin for even distribution and incredible strength. After the hull is rotated to the upright position and the jig removed, the topsides will have their structural inner skin vacuum bagged in place and the joints between the four separate parts will be joined together, creating a structural monocoque assembly.

Interior Modules and Systems Installation

After rolling the hull, it and the deck are moved to Lyman-Morse’s Building 11, where the modular sub-structures — cabin soles, deck elements, and interior assemblies — are preinstalled to double-check structural fit. Once those major elements are checked off, next comes major systems including propulsion modules, twin diesel engines, and the critical soundproofing. For reducing motion, the Hood 57 will also feature a Seakeeper computer controlled anti-roll gyro system.