February flew by, but not so quickly that we couldn’t pull together a photo presentation of the refit we did on Scout, a 1930s commuter yacht, plus an interview with the captain of a Swan 100 and a final push for Anna to win a major international award. Our monthly Dispatches give you an in-depth look at an assortment of projects we’re working on in both Thomaston and Camden.

In this issue:

Back from the Brink: Refitting Scout

Big Boat, Big Systems: Q&A with Capt. Richard Archer

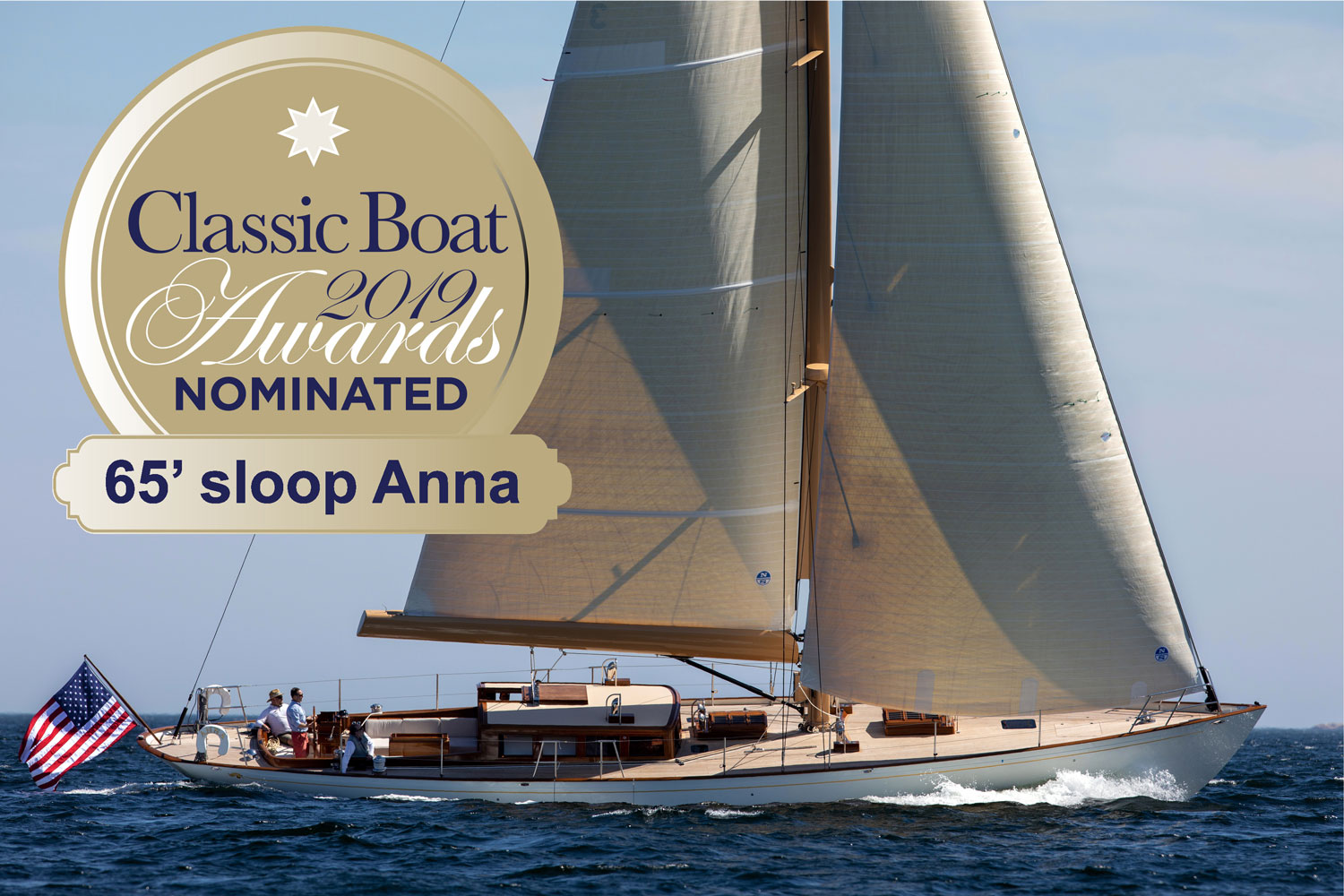

Vote American: Help Anna Win 2019 Classic Boat Award!

Back from the Brink: Refitting Scout

Originally commissioned as Comar in 1930, the commuter yacht Scout defined speed and luxury in American motor yachting. While able to accommodate a good-sized family, it was Scout‘s speed that made her shine, being able to sustain speeds that were faster than many cars of her era. Starting in the fall of 2017, a crew of about 20 Lyman-Morse carpenters, mechanics, and finish workers fitted Scout out with new timbers, twin modern diesels, a rebuilt generator, improved stabilizing trim tabs, tankage, and additional ballast and electronics.

Originally commissioned as Comar in 1930, the commuter yacht Scout defined speed and luxury in American motor yachting. While able to accommodate a good-sized family, it was Scout‘s speed that made her shine, being able to sustain speeds that were faster than many cars of her era. Starting in the fall of 2017, a crew of about 20 Lyman-Morse carpenters, mechanics, and finish workers fitted Scout out with new timbers, twin modern diesels, a rebuilt generator, improved stabilizing trim tabs, tankage, and additional ballast and electronics.

View a photo essay of Scout‘s refit project from start-to-finish.

Big Boat, Big Systems: Q&A with Capt. Richard Archer

Richard Archer has a unique role in the refit of a 13-year-old Swan 100 currently underway at Lyman-Morse’s boatyard in Thomaston, Maine. Rather than relying entirely on hired engineers to specify and design improved systems like the hydraulics, Process Logic Controllers, or propulsion systems on this high-end racer/cruiser, the professional captain has taught himself enough marine engineering to make many complex design choices himself. Archer has no fear whatsoever of specifying the electrical loads for a powered winch, summing up the power demands for both AC and DC electrics, or evaluating efficiencies that the refit will introduce into this 85-ton German Frers design.

Richard Archer has a unique role in the refit of a 13-year-old Swan 100 currently underway at Lyman-Morse’s boatyard in Thomaston, Maine. Rather than relying entirely on hired engineers to specify and design improved systems like the hydraulics, Process Logic Controllers, or propulsion systems on this high-end racer/cruiser, the professional captain has taught himself enough marine engineering to make many complex design choices himself. Archer has no fear whatsoever of specifying the electrical loads for a powered winch, summing up the power demands for both AC and DC electrics, or evaluating efficiencies that the refit will introduce into this 85-ton German Frers design.

To get a feel for where Archer gets his deeply intuitive sense for incremental performance gains on contemporary yachts, we sat down for a chat. All we are going to say is, if you ever meet this guy in a bar sometime, listen.

What were the big systems you evaluated on the Swan 100 that you skipper?

Besides all the cosmetics, there was the AC and DC electrical systems, the engine and propulsion that drove the boat, the hydraulics that powered the winches, and the Process Logic Controller (PLC) that integrated them all.

Those four things: AC, DC, PLC, and the hydraulics were the keys. They are interwoven.

Do you have an example for how they all fit together?

Let’s start with the starboard genoa winch. That winch is so big that you need hydraulic power to turn it. No human would want to grind it with a handle. It might appear there is simple motor that drives that winch, but in reality there are two complex power options that turn that fitting. One option is the dual 7.5-kilowatt DC-powered motors for lighter duty work. These are fast, quiet and work instantly. But they can’t trim the fully-loaded sail, when racing. For that, you need far more powerful Power-Take-Off (PTO) pumps. In normal mode, each PTO pump harnesses 15 kilowatts. But in beefier race mode, the same pumps produce a burly 33 kilowatts. This massive power comes directly from the generator’s heavy duty diesel-powered engine.

How do the PTO pump and the DC controller know when to start or stop? For that, a complex Process Logic Controller is needed to tell which pump to engage when. On our boat, the PLC only allows 11 kilowatts of DC electrical load on the generator. After that, there’s 15 kilowatts reserved for the PTO-powered pump to drive the winch for tougher work. Therefore, the PLC must be carefully programmed to monitor the winch loads and broker the handoff between the lighter-duty DC motor and the heavier-duty PTO pumps.

The PLC is always measuring how much power is needed, how much power can be shed, and where the energy must come from to do the needed work in a given situation. And it’s doing that subtle work for pretty much every system on the boat.

So similar monitoring is going on throughout the boat?

So similar monitoring is going on throughout the boat?

Yes. That is correct.

That implies that if Process Logic Controllers are not set up properly, at best, breakers blow.

Yes, that is also correct.

How do you sleep at night?

You develop a feel for what variables matter. If you keep doing your homework, and stick to the logic, the important data points emerge. I enjoy it, to be honest.

Does part of being a 21st-century skipper mean knowing when to delegate during a refit like this?

Absolutely. I am never doing this job alone. I am very careful to work with people I trust. For the PLC systems, for example, I use Marine & Hydraulics Finland for the planning and Lyman-Morse for the refit and installation.

But I still have to tell everybody very clearly what I want. The more details I tell them, the more details they need. Because, if am not specific enough and I leave it to others, I am going to end up with what they want and not what I want.

Can you give us a sense of the kind of efficiencies you will be gaining with this refit?

I think we are going to see something like 70 percent more flow in that core hydraulic component – that is a lot more power to do jobs around the boat. When we are racing, it is the capacity of the hydraulics that limits what we do. With the improved hydraulics, in terms of performance sailing, more complex maneuvers can happen more rapidly. Halyards can be raised faster. Spinnaker poles can be squared sooner and sails trimmed quicker. We estimate mark roundings should get about 20 percent quicker . That should yield about a 3 percent gain in speed per rounding. In a race, that’s a lot.

In terms of fuel efficiencies, that is somewhere around 11 percent. Again, that is a lot of money you save over 15 years. And a lot of carbon that does not go up into the atmosphere.

Vote American: Help Anna Win 2019 Classic Boat Award!

Earlier this year, we were thrilled to learn that Anna, our 65′ custom sloop, was shortlisted for the Classic Boat Awards 2019. This annual global design and naval construction award celebrates excellence in classic and modern-classic yachts from all over the world.

Anna was designed by Maine-based Stephens Waring Yacht Design and Martha Coolidge Design. And this boat is the only American vessel nominated in the competitive Spirit of Tradition category. The news attracted the attention of Maine media, including the Ellsworth American and we have had unprecedented love and support on social media.

Finalists will be announced in April and winners will fly to the United Kingdom for a deluxe award ceremony outside London. Past winners include such powerhouse boat builders as Vitters, Cheoy Le Shipyard, and others.

Online voting closes March 8. You can only vote once. A valid email is required.

Help us spread the word about high-quality Maine boat building around the world. Please vote now!

Click here to cast your vote for Anna today.

Want to make sure you don’t miss next month’s Dispatches? Click Here to have them sent directly to your inbox.